Power supply

Power supply from TRD.

In today’s technology-driven world, the demand for reliable and efficient power solutions is ever-increasing. From keeping our devices charged on the go to providing backup power during outages, electronic devices like Powerwalls, power banks, portable power stations, jump starters, and batteries play a crucial role. Here, we delve into the creation and functionality of these essential devices.

Powerwalls

Powerwalls are advanced battery systems designed to store energy for residential or commercial use. These systems are typically composed of lithium-ion cells, known for their high energy density and long lifespan. The manufacturing process begins with the production of individual battery cells, which are then assembled into modules. Multiple modules are combined to form a Powerwall. Key components include an inverter to convert DC power stored in the batteries to AC power, a battery management system (BMS) to monitor and optimize performance, and a thermal management system to ensure safe operation.

Power Banks

Power banks are portable chargers that store electrical energy and can recharge various devices like smartphones, tablets, and laptops. The core of a power bank is its battery, often a lithium-ion or lithium-polymer type. The creation process involves assembling battery cells, a circuit board with control chips, input/output ports, and a protective casing. The circuit board regulates power flow, ensuring safe and efficient charging and discharging. Design considerations include capacity (measured in mAh), output voltage and current, and safety features like overcharge and short circuit protection.

Portable Power Stations

Portable power stations are versatile, high-capacity power banks that provide electricity for larger devices and even small appliances. They combine large battery packs with multiple output options, including AC, DC, and USB ports. The production of portable power stations involves integrating large lithium-ion batteries, inverters, and complex BMS. Durability and portability are key factors, so these devices often come with rugged casings and carry handles. The BMS plays a critical role in managing the large energy loads and ensuring user safety.

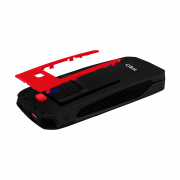

Jump Starters

Jump starters, also known as battery boosters, are compact devices designed to start vehicles with dead batteries. They typically feature high-capacity lithium-ion batteries capable of delivering a large burst of current. The manufacturing process includes assembling high-discharge battery cells, safety mechanisms to prevent reverse polarity and short circuits, and robust clamps for battery terminals. Advanced models also include additional features like USB charging ports and LED flashlights, making them useful emergency tools.

Batteries

Batteries are the fundamental building blocks for many of these devices. The creation of batteries involves several key steps: electrode material preparation, cell assembly, electrolyte filling, and sealing. For lithium-ion batteries, the electrodes are typically made of materials like lithium cobalt oxide or lithium iron phosphate. These materials are coated onto metal foils and assembled with a separator to form a cell. The cells are then filled with an electrolyte solution and sealed. The final stages include formation cycling to activate the battery and rigorous testing to ensure safety and performance.

Conclusion

The creation of electronic devices like Powerwalls, power banks, portable power stations, jump starters, and batteries involves sophisticated technology and meticulous engineering. These devices are crucial for modern life, providing reliable power solutions for a wide range of applications. As technology advances, we can expect even more efficient, powerful, and versatile power solutions to meet our growing energy needs.